Deep Space

RISD industrial designers at NASA—and in the private sector—gear up for the new space race.

LIFE IN SPACE IS HARD. There’s the moon dust, jagged as glass and capable of tearing fabric to shreds. Then there are the routine 500-degree temperature swings and the solar flares that can send deadly waves of radiation straight through the sturdiest space module. The challenges of negotiating microgravity aren’t exactly a walk in the park either. This much we know from Apollo 13.

More surprising to Molly Harwood 16 ID, when she was working as deputy manager of NASA’s Soft Goods Lab, were stories astronauts told her about other cosmic hardships.

“One astronaut said that when he returned to Earth it felt like a huge visual relief to just look at the carpet in his house,” she says, “because it was a plain, solid color compared to the walls of the International Space Station that are covered in stuff, with wires floating everywhere.” In fact, she says, astronauts on the ISS are constantly losing things—shoes, laptops, tools—because of the sheer “visual noise” of the environment.

Minimizing optical clutter is the kind of design challenge Harwood and other RISD alums working in space-related design love to grapple with. They feel well equipped to do so thanks in part to a robust series of programs and collaborations with NASA that RISD has developed over the past three decades.

With plans afoot to send astronauts back to the lunar surface—through NASA’s Artemis mission—and a longer-term vision to establish a sustained human presence on the moon as a training ground for exploration of Mars, interest in the space program is high, with speculation abounding around the likely time frame for when—not if—the first subdivision on the moon will be built.

One of the biggest challenges of designing for space, says Harwood, is that you are “designing everything for this person in an environment that you’ve never experienced and probably will never experience, and so it’s very hard to empathize with them fully.” Listening to astronauts talk about living in space helps, as do tests in similar environments (Hawaii, Iceland, New Mexico), but nothing can compare to the actual experience.

Deep space has captured our imaginations of late with rovers crawling across Mars and the launch of the James Webb Space Telescope, but down in lower orbit there has been a continual human presence on the International Space Station for the last two decades. In other words, plenty of work out there for industrial designers.

Two NASA labs in particular—the Center for Design & Space Architecture and the Soft Goods Lab—both located at the Johnson Space Center, in Houston, have hired RISD alumni as industrial designers. RISD grads have also forged careers at private space agencies such as SpaceX, Axiom Space and Blue Origin.

Skye Ray 16 ID, design lead at NASA’s Soft Goods Lab, has worked on a slew of items for the interior of the Orion capsule, the spacecraft that is scheduled to carry four crew members, including the first Black astronaut and the first woman, into deep space in 2026 (last year, Orion completed an unmanned flight around the moon). Ray and his team have designed everything from acoustic covers to absorb the constant sound of machinery—living in space is extremely loud—to the seat cushions the astronauts will sit on during launch to the kits and bags they will use during their time in the module. He also works on spacesuits and thermal blankets and recently designed a cover for a new type of camera astronauts will use during their explorations on the moon.

“You have to really think about how every single thing gets used,” Ray says, “not only because it’ll float away but also because your user is probably using their other hand to hold on to something or use a tool. They’re not there to interface with your beautifully designed object. They don’t really care about your object. They have a job to do. It’s our job to make their interaction with our objects as simple as possible.”

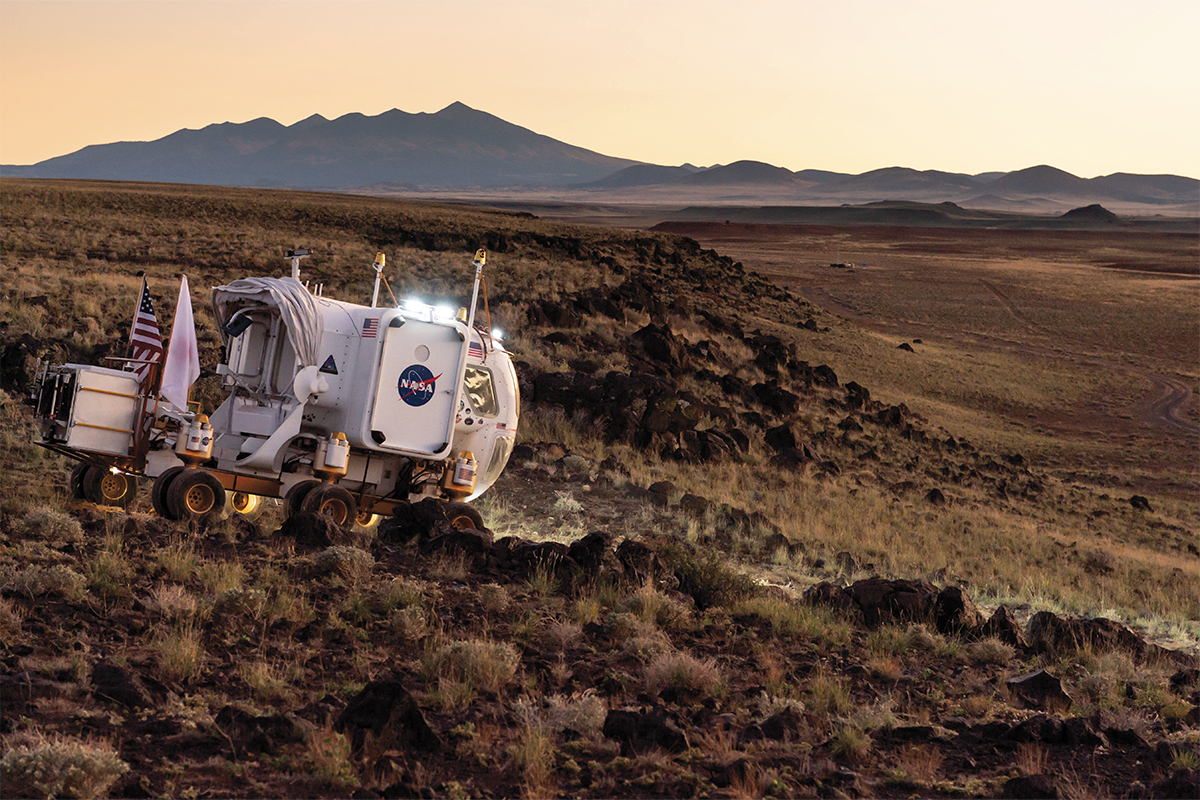

Lily Douglas 20 ID, an industrial designer in NASA’s Center for Design & Space Architecture, works on the layout of future habitats and rovers, many on decades-long timescales.

Typically, a project will start with a set of requirements—how many people need to fit in the module, how long they will be living in it, what kind of research they will be doing, what equipment they will need. Douglas and her colleagues generate a design and a more granular list of requirements and mock up prototypes, at which point the project gets contracted to a vendor such as Northrop Grumman or SpaceX. After that, Douglas may help to flesh out the design further, as she is currently doing with HALO (Habitation and Logistics Outpost), a module where astronauts will live and do research while visiting Gateway, the space station that will orbit the moon as part of the Artemis mission.

A self-confessed space nerd from an early age, Douglas first dipped her toe into aerospace design in a Design for Extreme Environments studio course at RISD taught by Industrial Design professor and NASA coordinator Michael Lye, who also helps place students in NASA summer internships and advises the RISD Rover Team that competes in the annual NASA Human Exploration Rover Challenge, in Huntsville, Alabama.

Designers face a long list of constraints that demand creative solutions when designing for space. Gravity, or the lack of it, is the most obvious. “When we’re designing habitats for the lunar surface,” Douglas says, “we need to take into account that people are going to be moving very differently. You have to worry about whether they are going to bash their heads in a tight environment.” Handles sticking out into aisles are a potential hazard, because even though a person on Earth may be able to just walk from one place to another, a person on the moon, she says, might need to bounce, bunny hop or jump from one side to the other.

“We thought a lot about disabled populations in Michael’s Design for Extreme Environments studio,” says Douglas. “The philosophy being that if you consciously design for the least-abled people, you make a better design for everybody.” And in a way, she says, astronauts are similar to persons with disabilities in that they have specific challenges in the ways they navigate space. “They don’t have gravity to anchor them to a specific workstation,” she says, “so they need the ability to hook their feet around something, and our job is to make that foot hook as comfortable and as secure for them as possible.” Astronauts on the ISS frequently develop rough calluses on the tops of their feet from hooking them underneath the handrails.

The really big deal for life on the moon that everyone is trying to figure out how to cope with is regolith, otherwise known as moon dust. Unlike Earth dust, which gets eroded by wind and water and has smooth edges, regolith has nothing to wear it down and is spiky and sharp. When it gets inside fabric (on a spacesuit for example, as happened during Apollo’s moon-landing missions) it rubs against itself and can tear the material to pieces. If it finds its way into mechanical systems, they will seize and bind. It clings to every surface.

Custom fabrics that can resist being ripped up by regolith will be needed for future NASA missions where astronauts will spend sustained periods on the moon looking for water. Extremely thick and hard to puncture, the fabric presents its own set of chal-lenges when it comes to sewing, says Ray in the Soft Goods Lab. “It’s a learning curve.”

ENGINEERS HAVE BEEN DESIGNING components for space travel for decades, so what do industrial designers, and RISD-trained industrial designers in particular, add to the field?

“Engineering teams tend to be very deterministic,” says Robert Howard, co-lead of NASA’s Center for Design and Space Architecture, who has overseen many RISD interns in his lab, a fair number of whom have been hired to work fulltime. “Engineering’s bias is toward addressing and overcoming the forces of nature, so they’re going to want to look at pressures, gravities, temperatures—they’ll think from that vantage point. Whereas the industrial designers are coming from more of an experiential perspective.”

Ultimately, what industrial designers bring to human spaceflight, says Howard, is humanity. “That’s the value of their contribution. They remind us that it’s not just about balancing equations, it’s about bringing humanity.”

While engineers can sometimes lose track of the fact that they’re designing for “human beings who are going to be inside this tin can,” says Michael Lye, RISD students “are much more focused on trying to design an experience and a life for the people inside of the spacecraft or habitat.”

Knowing how to build things makes them better designers for space, too, says Howard, because “if you’ve built things, you understand how the physical hardware actually works.” A medical workstation mock-up built for Howard by Carl Conlee 05 ID and Evan Twyford 05 ID almost two decades ago is still in use today as part of HERA (Human Exploration Research Analog), a three-story space-simulation habitat at the Johnson Space Center, where astronauts live and work in isolation for 45 days to study confinement and remote conditions.

Figuring out a way to make life in space feel “more comfortable, more habitable, more aesthetically pleasing, more psychologically pleasing” is inspiring to RISD alumni like Ray.

“If you look inside a lot of the habitats that are currently in use, like the ISS, they’re pretty stark,” he says. “As we start to look at habitats where people would be spending a lot more time, a Mars habitat for example, we have to think about how we could change the design of objects not only to be lighter in weight but also to feel more personal and pleasing to an individual.”

Tweaks could include padding the walls to deaden the sound of all the machinery and ventilation, angling walls to reduce echoes, or designing fabric sling seats in recreation areas, like hammocks that “hug” the body and help people feel more relaxed.

Sometimes it’s the little things that make a difference, says Bryan Cloyd, who was an industrial designer in NASA’s Habitability Design Center and now develops products at Apple. He helped the team working on a new toilet design for the International Space Station.

“If you’ve ever seen a photo of the old ISS toilet, it’s archaic to say the least,” he says. “You have all these little tiny buttons that do different things and are labeled really small. I worked with them to make that a lot more user-friendly and approachable.”

From her experience working at NASA on both habitats and soft goods, Harwood (who now works as an industrial designer at Google) says she did come across engineers who paid attention to the nuances of human experience, but she also encountered “plenty who were like, ‘Here’s a box. I’ve made the box. It meets the requirements. I did the thing. We’re done.’”

As well as having an ingrained sensitivity to the human and holistic experience of everyday objects, Harwood says, industrial designers also believe in the value of sketching and making as ways to think through a problem. “A lot of times engineers go straight to, ‘Here’s my final CAD,’ and I’m like, ‘No, no, we can sketch a little first.’”

Ray says that prototyping can help designers and engineers who have modeled an entire project in CAD. “We’ll make a real-world version and they’ll say, ‘Whoa, I didn’t really understand the scale at all,’ because they had no point of reference in CAD.” By prototyping early on, he says, you can find out what’s wrong with your assumptions and figure out “the hidden gremlins, the unknown unknowns that can turn into huge problems over time.”

IN SUCH A STEM-FOCUSED WORLD, respect for the role of human-centered design has taken a while to gain traction. When Conlee was hired to join the Habitability Design Center, in 2006, it was “sort of a fledgling group that was being kicked off to really focus on design” in what had been perceived as an engineering development process.

“It was neat to be a part of something that seemed really big,” says Conlee, “but it could also be frustrating because design wasn’t a high priority for most of the community there.” Conlee thinks there has been an evolving understanding of well-being within NASA. “Back in the ’60s and ’70s, they were recruiting these hard-core military guys to perform missions, and so there was a very binary approach to problem-solving: Does it work or does it not? If the human gets the work done, if the human comes back alive, it works.”

In time, Conlee says, various discomforts bubbled up. “I think the reason anybody cared initially is because people’s performance was measurably worse, and since it was such an investment to get people up there, they figured it’s probably worth being thoughtful about how they experience their environment. When people would come back after doing Hubble telescope or satellite repairs, and their fingers would be raw, with skin coming off, that was pretty clear evidence that some improvements needed to be made to spacesuits, for example.”

Harwood remembers being the first industrial designer hired in the NASA Soft Goods Lab, in 2018. “Because of the combination of design and the human focus of the objects, it was clear this should be a very industrial-design-friendly space, but we had to work hard to validate our role,” she says. “I lost count of how many times I was called a seamstress or referred to as the ‘64-Crayola-box-set girl,’ who could be relied on to make pretty renderings. I think people’s minds were changed when we produced valuable work and designed solutions for them.”

As the broader commercial sector of human spaceflight gathers momentum, NASA’s Howard sees ever more opportunities for industrial designers to play a key role. “We’re leaving the era where human spaceflight was something that only the government could do. In the future, who knows who’ll be going to space and for what reason? If you have a flight full of billionaires who want to go up to space to play, all of a sudden, things that don’t really matter on a science mission are going to become paramount.”

There are no rooms dedicated to gameplay on the ISS, but a space tourism hotel would likely have just such a facility, muses Howard. Personal grooming might be a priority, too, with workstations devoted to hairstyling and beauty treatments. “When science is the mission, comfort is addressed in the context of enabling the science,” he says, “but for space tourism, customer experience is the mission and part of that experience is comfort and aesthetics.”

And once a sustained presence on the moon is established, wouldn’t it be handy to have someone on-site to make and fix things? That job sounds appealing to Ray. “Obviously, there’s going to be a pilot, people with medical backgrounds, scientists, and that’s all superessential,” he says, “but if designers could design and make solutions in situ, that would be a huge asset for an isolated outpost on another planet.”

Lily Douglas is contracted to NASA through KRB. Skye Ray is contracted to NASA through Jacobs Engineering.

Words by Judy Hill.